|

Laboratory

.

Research Laboratory

In Applied Mechanics Department, our institute has Concrete Technology Lab, Mechanics of Material lab and NDT labs are present as research laboratories. Concrete Technology Laboratory provides facilities to conduct all quality control tests on cement, aggregates and concrete (Fresh and hardened). Students learn the standard procedure to test the quality of building materials in line with the corresponding IS codes. The NDT lab has equipment for conducting non-destructive tests on concrete to verify quality in the post-construction phase. In addition to meeting the curriculum and consultancy requirements, the equipment in the laboratory are extensively utilized for projects by students of UG, PG and also by faculty for their research work.

Mechanics of materials laboratory is well equipped with destructive testing machineries. This lab course is offered in the second year for the students from various departments in the school of mechanical engineering. Students will be able to understand the theoretical concepts of solid mechanics course and enable them to apply it practically in this laboratory. Different types of tests are conducted in this laboratory as per standards (ASTM and IS) to know the various mechanical properties of a material such as young’s modulus, shear modulus, hardness, toughness, deflection, fatigue strength etc. All the equipments are properly calibrated and tested by the manufacturer in a periodic manner. Final year Student’s project works on testing of various materials like composite materials have also been done in this laboratory.

The list of equipments are attached below which are present in our concrete technology laboratyory.

Fig.1 Loading Frame

Loading Frame is equipment used to test the Various structural elements like Beams. Columns, Slabs and portal frames or any other Structural Elements for its Compression and Flexural strength. Our loading Frames are Provided with Safety Features like Over load Protection, Over pressure Protection. Recently, our department has purchased loading frame in 2019 . This loading frame has capacity of 100T. It costs Rs.22,47,900.

Fig 3.Air Permeability Apparatus

Air permeability apparatus is also added to our bunch of instruments recently. This equipment meets the requirements of DIN-1048 and is used for determination of the imperemeability of cement, mortar and concrete specimens either cast in the laboratory or obtained by cutting out cores from the existing structures. The apparatus is manufactured in the following models:

Three Cell:Size; 200 mm× 200mm× 120mm High

The cost of electric air compressor having 150 psi capacity 230 V, 2 hp, 50 Hz which is supplying compressed air 5 kg/cm2 to 15 kg/cm2 with assembly for permeability test of concrete apparatus is Rs.85,904.

The equipment’s main components of the apparatus are impermeability sample holding device assembly with stand, water reservoir and pressure regulation arrangement.

The next instrument in our lab is for Non Destructive Testing i.e. Rebound Hammer.

Fig.3 Rebound Hammer

Rebound Hammer test is used to find out the compressive strength of concrete by using rebound hammer as per IS 13311 (Part2) 1992. The underlying principle of the rebound hammer test is: The rebound of an elastic mass depends upon the hardness of the surface against which its mass strikes. When the plunger of the rebound hammer is pressed against the surface of the concrete, the spring controlled mass rebounds and the extent of such a rebound depends upon the surface hardness of the concrete. The surface hardness and therefore the rebound is taken to be related to the compressive strength of the concrete. The rebound value is read from a graduated scale and is designated as rebound number or rebound index. The compressive strength can be read directly from the graph provided on the body of the hammer.

The specifications of the rebound hammer in our laboratory are as follows:

Digital and mechanical display with printer and connectable live to th iOS via data transfer module to the instrument of the following specifications. A 4.7 inch retina HD touchscreen display, 1.84 GHz 64-bit A8 chip, 1GB RAM,32GB ROM, 8 MP Rear and 1.2 MP Front camera, 1810 mAh Battery, Hammer range 10 to 70 n/mm2.

Some of the research was done in the laboratory are listed here. An experimental investigation on polymer modified fibre reinforced concrete by using crushed sand and natural sand was done by Kadam Rahul T. in year 2018. Another research ‘An experimental investigation on structural properties of the polymer modified fibre reinforced concrete using manufactured sand was done by Patil Yogesh Y. in 2018. An experimental investigation on metakaoline modified fibre reinforced concrete was done by Gaikwad Girija Vidnyan in 2019. An experimental investigation on structural properties of polymer modified fibre reinforced concrete was done by Darade Ashish Vitthal in 2019.

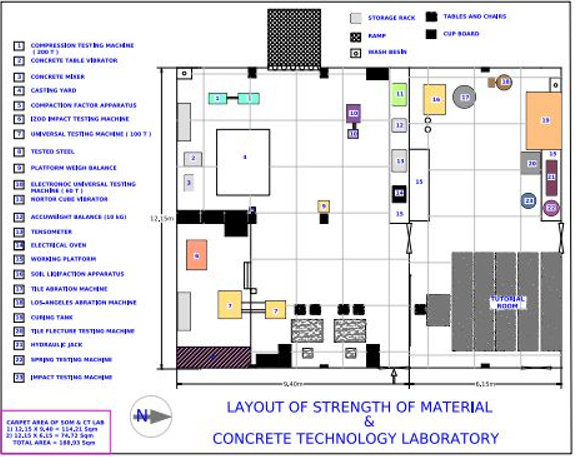

Fig 4.Layout of SOM lab

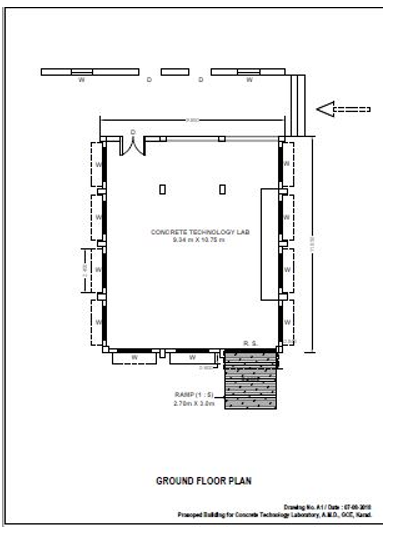

Fig 5.Layout of CT Lab

This is our research laboratory and some important instruments are listed here. The lst of remaining instruments is attached here also.

|